Design Services

Overview

At Inzide, we understand that flooring is the foundation of every great space, thoughtful design can elevate interiors to create truly impactful environments. Choosing the ideal flooring solution can be tricky, that’s why we offer a comprehensive design service, tailored to your project’s unique needs, challenges, and vision.

Whether you’re working with standard products or exploring custom options like printed Forbo vinyl or bespoke yarn selections for Interface carpet tiles, we can guide you through the process to bring your vision to life. From initial concept design to detailed floor plans and detailed 3D renders, our team is here to help you craft a space that meets your technical, sustainability, and aesthetic requirements—all within your budget.

Crafting your vision

Meet Stella

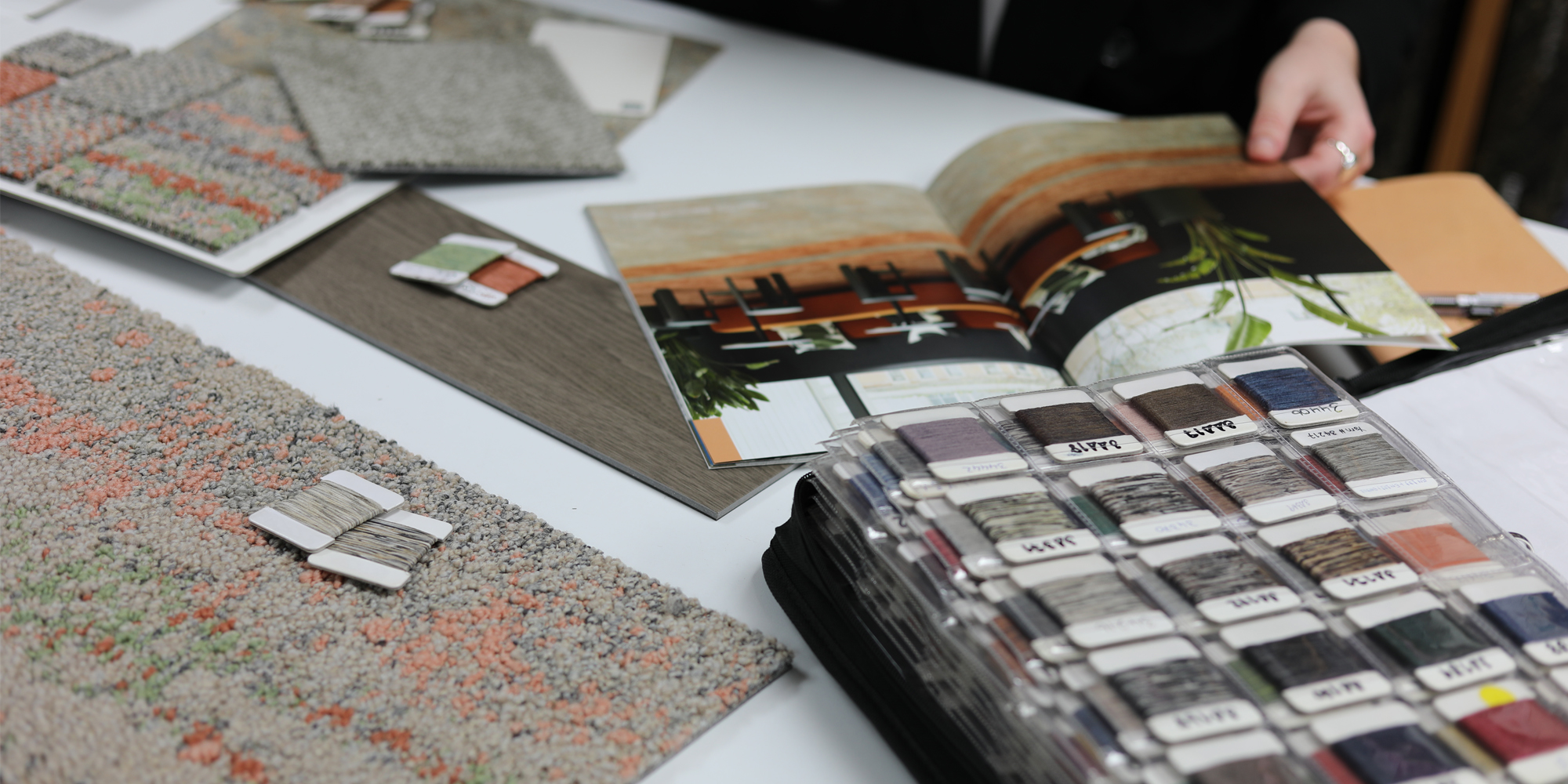

Stella is our talented in-house Flooring Concept Designer with a keen eye for detail. Stella has a bachelor’s degree in Architecture and a Diploma in Commercial Interior Design, and has a wealth of knowledge of all Interface, nora and Forbo collections.

With thousands of options out there, knowing the intricacies of each collection right down to the yarn type, thickness, transition type and installation orientation can be the make or break of great flooring design.

Stella is available to work on projects that require a high level of design detail, creating detailed floor plans and renders to help you visualise the final result before committing to a collection, colour scheme, or layout.

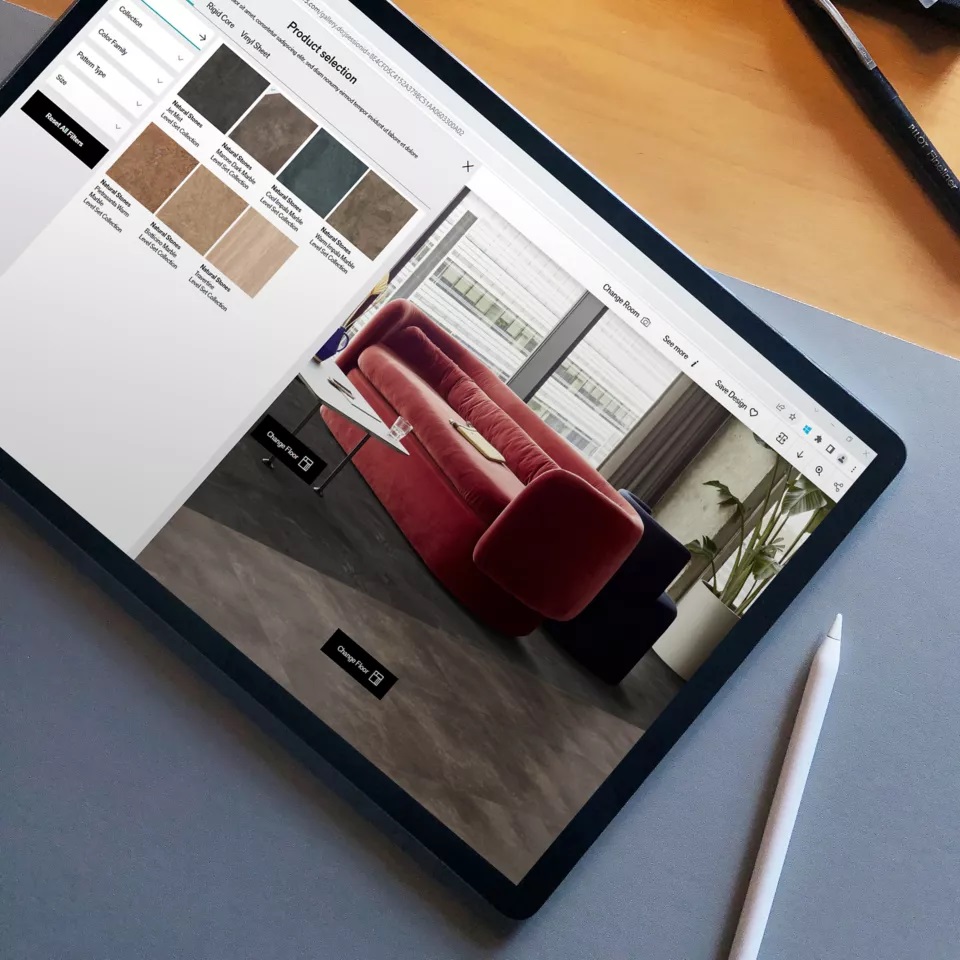

Floor Visualiser tools

You can upload a photo of your space into these floor visualiser tools to see how standard products will look in your environment, or explore a selection of pre-designed room scenes to discover the perfect product for your project.

Visualize your commercial flooring design project and see it in your space with Interface’s commercial floor design tool.

Visualize Forbo floors in different interiors with our online floorplanner. Upload your own room image and create, share and save your floorplans.

The fully featured nora Room Designer allows you to see how quickly and easily nora rubber flooring can fit into your building project.

Custom Carpet Tile Projects

Custom Resilient Projects

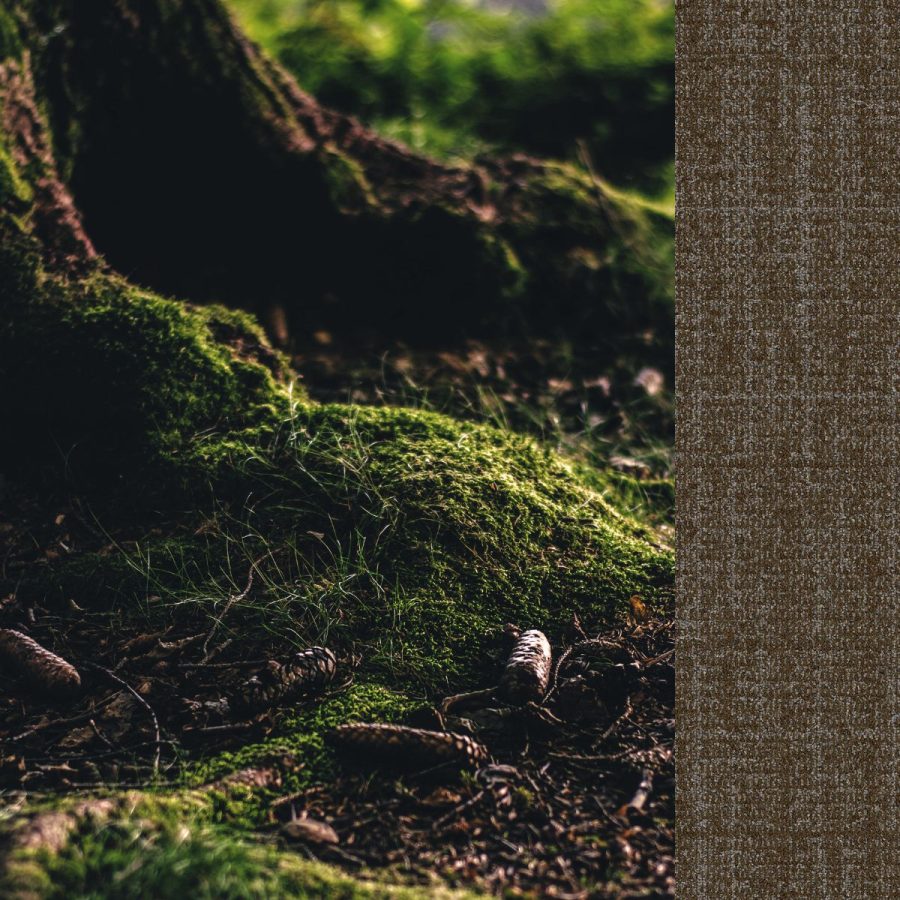

2026 Colour Forecast

Drawing inspiration from the natural world, these palettes capture the grounding tones of earth and stone, the refreshing hues of water and sky, and the warmth of organic textures. Each colour story is curated to bring balance, depth, and connection into interiors, creating flooring solutions that feel both timeless and on-trend.

Palettes

Custom Flooring

Do you have a project that needs custom flooring?